Should we pay attention to the UV light pressure when we choose a suitable UV intensity sensor?

Yes, we must!!

Low-pressure (LP) UV lamps and medium-pressure (MP) UV lamps are two different types of ultraviolet (UV) lamps commonly used in water treatment systems for disinfection purposes. The main differences between them lie in their design, wavelength spectrum, and applications. Understanding these differences is important when selecting a suitable UV intensity sensor for a particular UV lamp type. Here’s a breakdown of their distinctions:

Design:

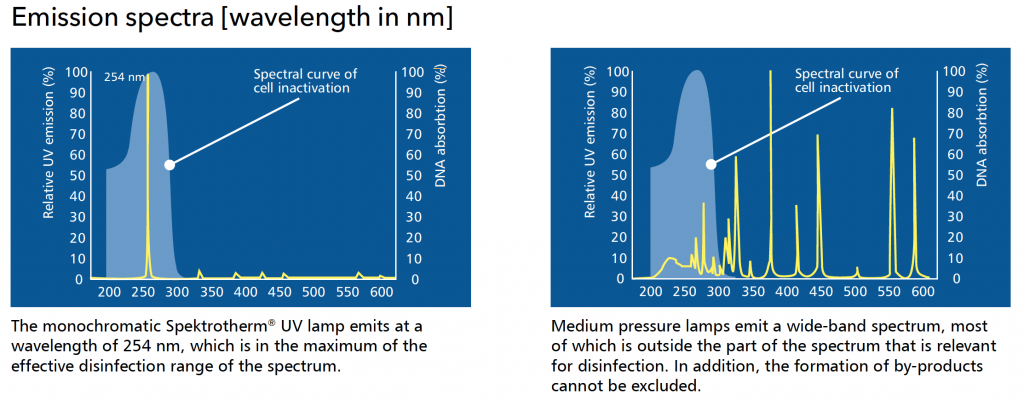

Low-Pressure UV Lamps (LP): LP UV lamps are characterized by their long, slender shape. They operate at a low pressure and typically emit a monochromatic UV light at a specific wavelength, usually around 254 nanometers (UVC range).

Medium-Pressure UV Lamps (MP): MP UV lamps have a thicker, more robust design. They operate at higher pressures and emit UV light across a broader spectrum, including UVA, UVB, and UVC wavelengths.

Wavelength Spectrum:

Low-Pressure UV Lamps (LP): LP lamps primarily emit UV light at a specific wavelength, typically around 254 nm (UVC). This wavelength is effective for germicidal applications.

Medium-Pressure UV Lamps (MP): MP lamps emit UV light across a wider spectrum, including UVA, UVB, and UVC. While they still provide germicidal effects, they also have applications in processes where a broader UV spectrum is beneficial, such as advanced oxidation.

Applications:

Low-Pressure UV Lamps (LP): LP lamps are commonly used in water disinfection applications where the primary goal is to inactivate microorganisms, such as bacteria and viruses.

Medium-Pressure UV Lamps (MP): MP lamps find applications beyond disinfection. Their broader spectrum makes them suitable for processes requiring advanced oxidation, where organic and inorganic contaminants are targeted.

When choosing a suitable UV intensity sensor, it’s crucial to consider the type of UV lamp used in the water treatment system:

For Low-Pressure UV Systems:

A UV intensity sensor is designed to measure a broader spectrum of 210~375nm for Low-Pressure UV Systems because of the wavelength emitted by low-pressure UV lamps (around 210~280 nm only UVC).

For Medium-Pressure UV Systems:

A UV intensity sensor is designed to measure a narrower spectrum of UV wavelengths (Only UVC 210~280nm) for medium-pressure UV systems. A medium-pressure ultraviolet lamp not only emits UVC (ultraviolet C) but also generates UVB (ultraviolet B) and UVA (ultraviolet A) as byproducts.

It’s essential to match the characteristics of the UV intensity sensor with the specific UV lamp technology employed in the water treatment system to ensure accurate and reliable monitoring. Using the wrong type of sensor may result in inaccurate readings and compromise the effectiveness of the UV disinfection or treatment process.

Leave A Comment